SPIRAL BAFFLE BOARDS - "A" Type Tube

SPIRAL BAFFLE BOARDS - "A" Type Tube

SPIRAL BAFFLE BOARD

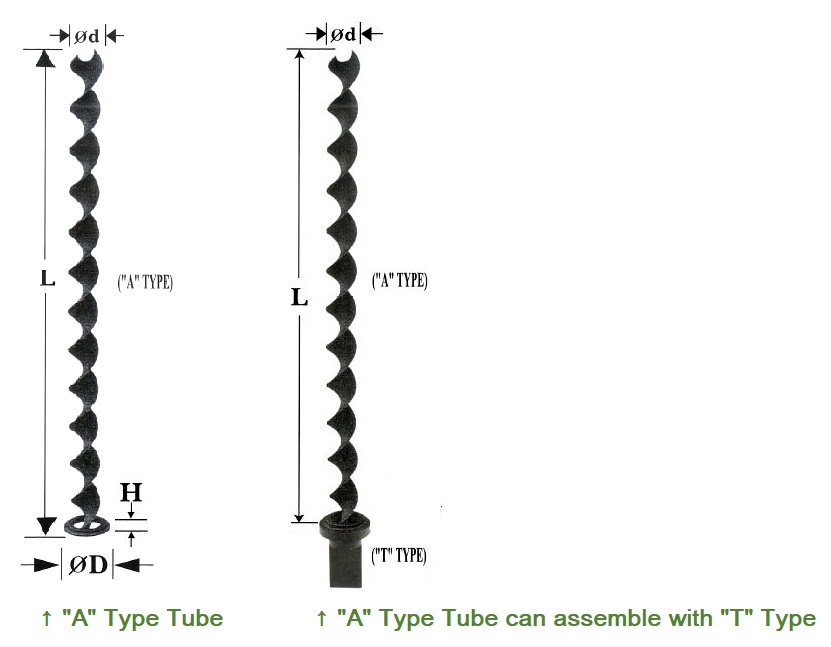

"A" Type Tube

SIZE

| Item No. | øD (mm) |

L (mm) |

O Rring | øDx H (mm) |

| ST-A08100 | ø8 | 100 | P:10 | 15x4 |

| ST-A08200 | ø8 | 200 | P:10 | 15x4 |

| ST-A08300 | ø8 | 300 | P:10 | 15x4 |

| ST-A10100 | ø10 | 100 | P:12 | 18x4 |

| ST-A10200 | ø10 | 200 | P:12 | 18x4 |

| ST-A10300 | ø10 | 300 | P:12 | 18x4 |

| ST-A12100 | ø12 | 100 | P:16 | 22x4 |

| ST-A12200 | ø12 | 200 | P:16 | 22x4 |

| ST-A12300 | ø12 | 300 | P:16 | 22x4 |

| ST-A16100 | ø16 | 100 | P:20 | 25x4 |

| ST-A16200 | ø16 | 200 | P:20 | 25x4 |

| ST-A16300 | ø16 | 300 | P:20 | 25x4 |

| ST-A20100 | ø20 | 100 | AS:119 | 30x4 |

| ST-A20200 | ø20 | 200 | AS:119 | 30x4 |

| ST-A20300 | ø20 | 300 | AS:119 | 30x4 |

| ST-A20400 | ø20 | 400 | AS:119 | 30x4 |

| ST-A25100 | ø25 | 100 | AS:121 | 35x4 |

| ST-A25200 | ø25 | 200 | AS:121 | 35x4 |

| ST-A25300 | ø25 | 300 | AS:121 | 35x4 |

| ST-A25400 | ø25 | 400 | AS:121 | 35x4 |

Note:

(1) Spiral Baffle Board - "A" Type Tube include O-Ring (without Plug and "T" Type).

(2) "A" Type Tube can assemble with "T" Type.

If you would like to know more, please feel free to CONTACT us.

How to Fit in Mold?

Fit A type with T type in the Mold :

Why Choose Spiral Baffle Board?

Revolutionary innovation is great news for mold users.

Spiral Baffle Board conducts heat quickly away from the mold, providing the optimal cooling effect and so reducing costs.

Comparison

| Conventional Cooling Baffle | New Spiral Baffle Board | |

| Tooling Method | Complex | Simple |

| Tooling Cycle Time | Long | Short |

| Fitting with Tooling | By Case | Good |

| Water Flow Phenomenum | Laminal Flow | Turbulent Flow |

| Cooling Effect | Uneven | Even |

| Price Cost | Higher | Lower |

| Injection Mold Cost | Higher | Lower |

| Conclusion |

Production Cost Higher. Part Quality isn't so good. |

Production Cost Lower. Part Quality is good. |

If you would like to know more, please feel free to CONTACT us.